Unlocking the Power of Precision: The Ultimate Guide to Shaft Design and Engineering

Imagine you’re at a bustling factory, surrounded by the whirring sounds of machinery, each part working in perfect harmony. In the heart of this orchestrated chaos lies a crucial component that you might take for granted: the shaft. Whether it’s a drive shaft that transfers power from the engine to the wheels of a vehicle, or a support shaft that bears the weight of moving parts, mastering the fundamentals of shaft design is key to enhancing engineering solutions. But what makes a shaft truly effective? What secrets lie within the realm of shaft engineering that can elevate your projects to the next level?

Shafts come in various shapes and sizes, from simple rods and poles to more complex axles and spindles. Each design serves a unique purpose and understanding the nuances of shafts can unlock the potential of any engineering endeavor. But the journey toward effective shafting is not one to be taken lightly. It requires a solid foundation in the principles of mechanical engineering combined with a dash of creativity. Have you ever wondered how engineers select the right shaft for a particular application? Spoiler alert: it’s an intricate blend of physics, material science, and a touch of art.

One critical consideration in shaft design is the load-bearing capacity. Whether you're dealing with transmission shafts or power shafts, the ability of the shaft to withstand operational stress without deforming is paramount. "Design isn’t just what it looks like; it’s how it works," Steve Jobs famously said. This quote perfectly encapsulates the essence of shaft engineering. It’s not just about making a piece of metal; it’s about crafting a solution that effectively transfers forces while enhancing the machinery’s functionality. So, how can you ensure that your shaft assembly meets these rigorous demands?

When venturing into shaft engineering, it’s vital to focus on key attributes such as material selection, geometry, and stress analysis. For instance, using high-strength steel for a rotational shaft can improve durability significantly. Additionally, a well-designed shaft bearing can greatly reduce friction and mechanical wear, extending the lifespan of your machinery. Questions to consider include: What materials are optimal for your design? How will the design affect the overall machinery performance? By evaluating these factors, you can create a shaft that not only meets specifications but exceeds expectations.

In conclusion, mastering the fundamentals of shaft design is more than an engineering necessity; it’s an empowering journey that enhances your problem-solving capabilities. Whether you’re designing a new bar for a piece of equipment or refining a spindle for better efficiency, the principles you apply will shape the future of your mechanical solutions. Investing time in understanding shaft assembly and its components will not only improve your engineering skillset but will ultimately contribute to a more effective and innovative industry. So, are you ready to dive deeper into the world of shaft design and engineering? Let’s get started!

Innovative Strategies in Shaft Engineering: From Concept to Creation

In the world of engineering, where power meets precision, shaft design and engineering play a critical role. But what does it really take to convert a simple concept into a fully functional shaft capable of carrying out extraordinary tasks? As we navigate through this intricate journey of shafting, from the initial spark of an idea to the full-fledged assembly, we will uncover innovative strategies that not only enhance the functionality of various mechanical shafts but also revolutionize the way we approach shaft assembly. Remember, behind every spinning axle or robust bar lies a story waiting to be told.

Imagine a bustling workshop, where engineers huddle over blueprints, their minds racing with possibilities. Each line on the draft represents not just design, but aspirations—each shaft, whether a drive shaft or a mechanical shaft, carries the promise of movement and power. In the heart of each innovative shaft design lies the potential to enhance machinery performance and efficiency. What if I told you that the key to unlocking the full potential of shaft engineering is rooted in understanding both the materials you choose and your intended application?

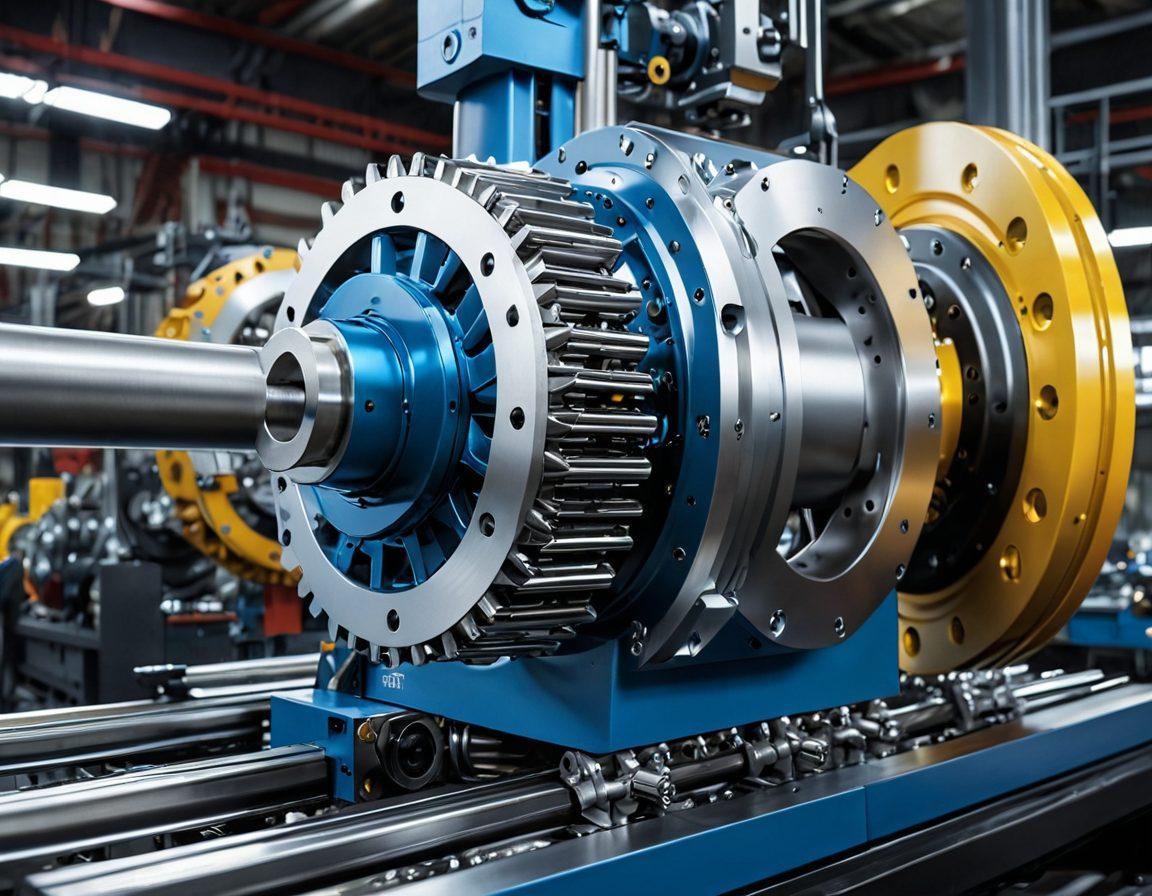

The process of shaft design is akin to piecing together a puzzle. Precision is essential; every rotational shaft functions optimally only when its components—piston, spindle, and support shaft—are meticulously engineered to reinforce one another. "Great design is all about the details," says famed designer Jony Ive. So how do we ensure that our shafts are designed with the utmost attention to detail? It begins with in-depth research. Robust data analysis will inform decisions about the kind of shaft bearings that suit your application best, whether it’s a transmission shaft in a vehicle or a support shaft in machinery.

Once you’ve determined the materials and design of your shaft, it's time to amplify that innovation—testing! Imagine your shafts whirring to life, each axle spinning in harmony with the others. But what happens when things go wrong? This is where iterative design comes into play. Engineers often iterate through numerous designs before achieving the perfect balance of durability and performance. Allow failure to teach you; each misstep is a stepping stone on the path towards engineering excellence. How have your past experiences shaped your current understanding of shaft design?

In a world that increasingly values efficiency, the role of modern machinery shafts can't be overstated. As we harness new technologies, the prospect of combining our traditional engineering knowledge with cutting-edge innovations presents itself. What if your concepts could blend with 3D printing for creating prototypes or advanced simulation software to predict shaft dynamics? By adopting these innovative strategies in shaft engineering, you unlock new doors to creativity while driving the sector forward. Always remember, with every shaft you design, you are not just creating a tool; you are laying the groundwork for future advancements in engineering and technology.

Understanding the Impact of Precision Shafting on Machinery Performance

Imagine a world where the gears of machinery grind to a halt, where each clink and clank of metal signals a breakdown in productivity. This scenario is a nightmare every engineer wants to avoid. Enter precision shafting, the unsung hero of modern machinery performance. Shaft design and engineering play a pivotal role in transforming raw energy into motion, and without precision, the entire system risks failure. So, what exactly is precision shafting, and how does it influence machinery performance? Let’s delve deeper into this fascinating topic, exploring how things like drive shafts, spindles, and axles come together to create harmony within moving parts.

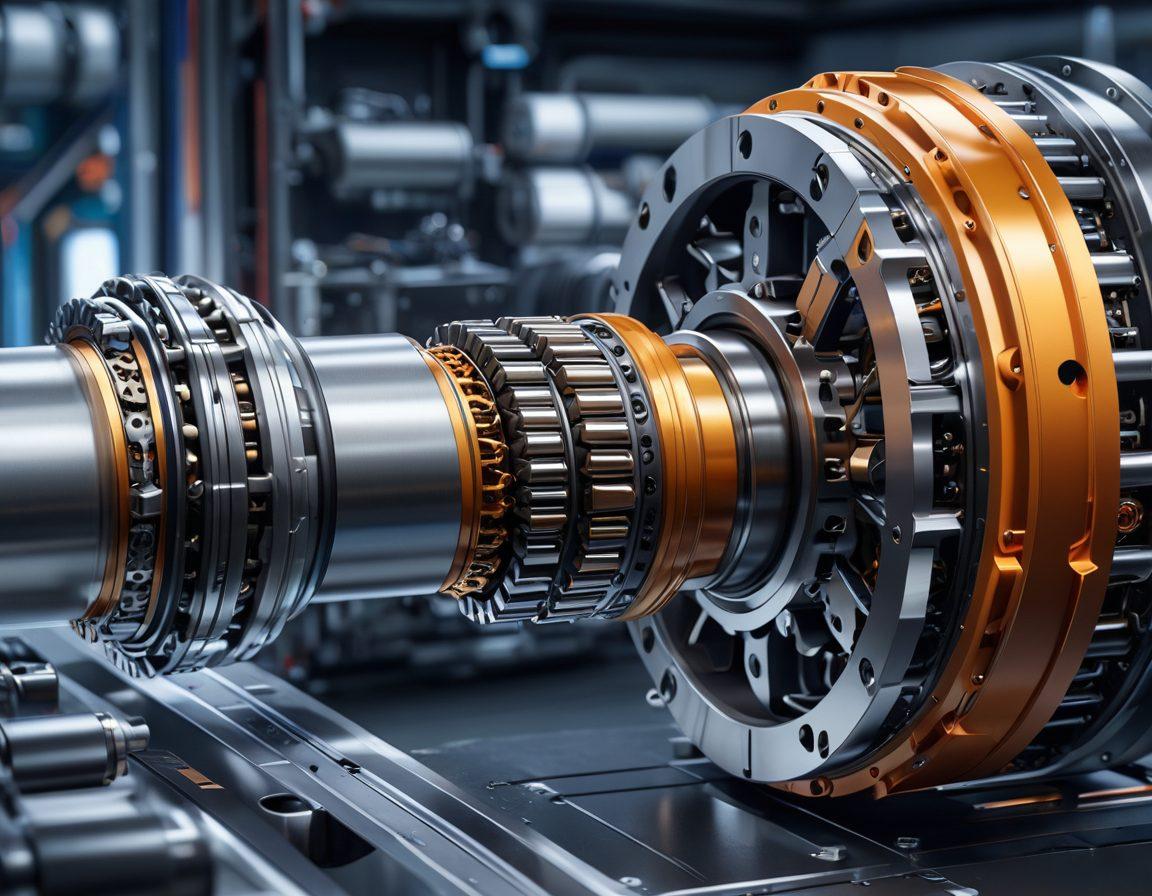

At its core, a shaft is a cylindrical component that transmits power and motion within machinery. But don’t let its simple shape fool you; the intricacies of shaft design can significantly impact a machine’s efficiency, durability, and overall effectiveness. For instance, think of a drive shaft that connects the transmission to the wheels of a car. If this shaft isn’t manufactured with precision, what happens? Well, you might experience excessive vibrations, wear and tear, and ultimately, decreased performance. In the words of engineer Henry Petroski, "Design is not just what it looks like and feels like. Design is how it works." That’s the essence of precision shafting; it’s not just about aesthetics but about functionality and reliability, too.

Have you ever pondered how a slight misalignment in a mechanical shaft can ripple through an entire system? It’s fascinating how something as innocuous as a shaft bearing can alter performance metrics. For every cylindrical Rod or Pole working behind the scenes, precision ensures they are working in tandem rather than at odds. Take the example of a transmission shaft in a vehicle. It must support rotating parts and withstand immense stress without compromising integrity. Therefore, proper shaft engineering is vital. By focusing on design details and tolerances, engineers can craft an axle that not only fits perfectly but also enhances the overall performance of the machine it supports.

Now, let’s discuss the significance of materials and finishes in precision shaft design. You might be wondering, how does the choice of metal impact a shaft's durability? The answer lies in the mechanical properties of shaft materials, which ultimately dictate how well they withstand force and wear. Common materials like carbon steel and stainless steel offer different benefits, but choosing the right one can make a tremendous difference in how a Machinery Shaft performs under load. A high-quality support shaft can last for years, while a poorly made one might falter after a few seasons of use. Engineers must become detectives, mining for clues on which materials will serve best under challenging conditions.

Finally, what actionable steps can be taken to ensure the effectiveness of your shafting projects? Regular maintenance checks, precise tooling, and the best practices in shaft design are critical. Paying keen attention to shaft support mechanisms ensures that the various components maintain their intended axis, reducing unnecessary wear. Precision in shaft assembly cannot be overstated—every twist and turn must align with exact specifications. The question you should ask yourself is: Are you ready to embrace precision in your shaft engineering endeavors? Remember, in the world of machinery, the smallest misalignments can spell disaster. By understanding the impact of precision shafting on machinery performance, you’re not just upgrading a system; you’re ensuring a legacy of reliability and efficiency.